Inventory Management

Softrader Cloud’s stock system inherits many of the core features of the stock system in Softrader 7. It has been perfected over nearly 30 years of use by companies supplying the oil industry, and has been built around strict requirements for traceability. At any point in an item’s journey through the system you can see exactly where that item is, and at what stage it is in the process. Even many years after an order has been shipped to your customer, you can still bring up all the certification details for that item.

Stock System StructureThe structure of the stock system in Softrader Cloud is both practical and elegant. It works on 3 levels:

Stock System StructureThe structure of the stock system in Softrader Cloud is both practical and elegant. It works on 3 levels:

Stock Codes: Each unique stock code contains a standard description, and much more information besides. You may save MESC numbers against it. It could have standard weights. Notes can be added. You can even upload technical drawings which can be produced every time you ship the product to a customer.

Shipment Records: Of course there may be many different shipments of a stock code. The shipments database holds a record of each of these, along with all the information from the incoming stock order.

Location records: For every shipment record, you may need to split the quantities of the shipment across many locations in the warehouse. Similarly, there may have been several different heat numbers on the shipment. The locations database is where all this detail comes in. Sales orders allocate directly against these location records, allowing you to choose in detail exactly what item is shipped to your customer.

Stock Coding SystemSoftrader Cloud’s unique coding system is fully customisable and allows you to build up comprehensive specifications from which all your stock is coded.

Stock Coding SystemSoftrader Cloud’s unique coding system is fully customisable and allows you to build up comprehensive specifications from which all your stock is coded.

You begin with the ‘Group Menu’. This is the first click your users make when coding a product. Perhaps they would choose from ‘Pipe’, ‘Fittings’, ‘Valves’. From that point on, the system will offer them a menu to fill a particular part of the specification for the product. For example, the valve menu may take you through the following options: Valve Type > Body Material > Trim Material > Bore Size > Ends. In this way, the system builds up a unique stock code and stock description for your product which can then be traced on it’s way through your system, from enquiry, to quotation, to stock holding, to shipping and eventually to invoicing.

The beauty of this system is that you can report on stock items along with traded items that you never brought in to stock.

Warehouse And Location ManagementIn Softrader Cloud, every stock item has a location in the warehouse or warehouses. Each unique combination of shipment, location, heat number and certificate number is identifiable to an exact point in the warehouse. Of course from this information it’s corresponding certificates can be found, and even any documentation relating to the original incoming shipment job.

Warehouse And Location ManagementIn Softrader Cloud, every stock item has a location in the warehouse or warehouses. Each unique combination of shipment, location, heat number and certificate number is identifiable to an exact point in the warehouse. Of course from this information it’s corresponding certificates can be found, and even any documentation relating to the original incoming shipment job.

When your staff produce a pick list, it provides them with all the information about where to find the product. It can even draw them a map of your warehouse showing exactly where the particular item is located.  Consigned StockOne of the features of the warehouse system in Softrader Cloud is that consigned warehouses can be created. If you are storing your stock at your customers’ premises, this allows you to limit the sale of that stock to a particular customer or customers. It also allows you to report on stock movements and stock quantities and values in that warehouse.

Consigned StockOne of the features of the warehouse system in Softrader Cloud is that consigned warehouses can be created. If you are storing your stock at your customers’ premises, this allows you to limit the sale of that stock to a particular customer or customers. It also allows you to report on stock movements and stock quantities and values in that warehouse.

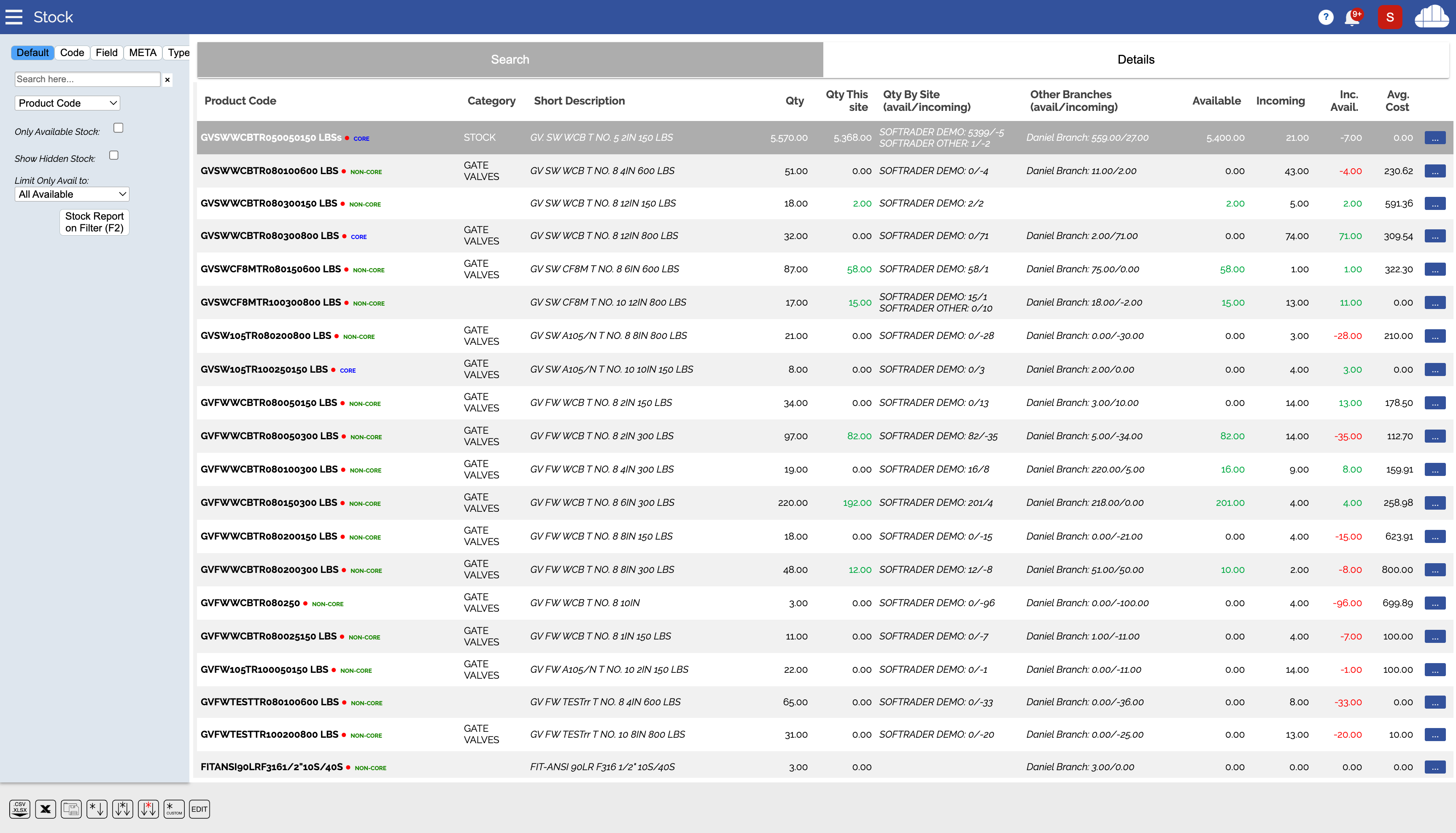

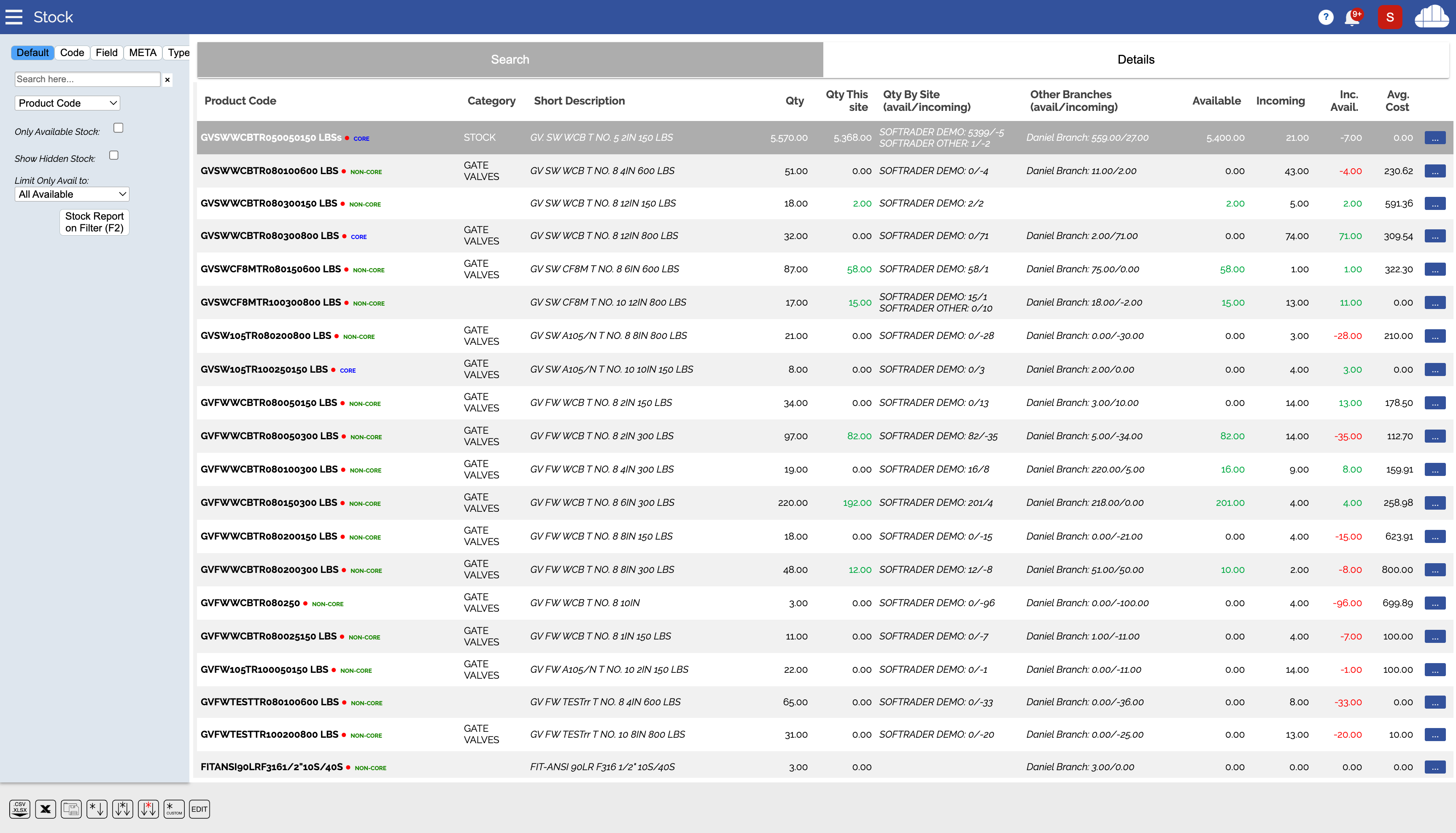

Existing stock can be relocated to a consigned warehouse using a ‘Stock Relocation’ job. This allows you to produce documentation for the move of the stock.  Stock ReportingWhether it be a detailed Movement Report, or a report of all the stock in the warehouse, Softrader's detailed stock reporting capabilities will mean you are always on top of your stock's value, it's age, and what needs reordering in time for you never to run low.

Stock ReportingWhether it be a detailed Movement Report, or a report of all the stock in the warehouse, Softrader's detailed stock reporting capabilities will mean you are always on top of your stock's value, it's age, and what needs reordering in time for you never to run low.

Stock location reporting allows you a detailed overview of every individual location in the warehouse and what it contains. The value, age and quantity of each item you hold can be found from this report. Like all the other reports in Softrader it is hugely customisable and can also be automated. Of course it can also be downloaded as a spreadsheet.

The Stock Movement Report tells you about every time the quantities in the system change. Whether it be a sale, a purchase, or even a stock take or manual amendment, all the details can be found in this report.

Because of the details stored in the stock movements, Softrader Cloud can also achieve accurate, to the minute, historic stock valuations. Every change being recorded means that you can look back in time to a specific point in the past, and see exactly what your stock holding was.

Stock TakesThe Stock Take system in Softrader Cloud is designed with practical ease of use in mind. Of course it works on the basis of a count of location records, but you can search the stock system by product code too. Most people select a range of location codes, then do their count in manageable chunks. This makes it very easy to do regular rolling stock counts. Much easier than a count of a whole warehouse.

Stock TakesThe Stock Take system in Softrader Cloud is designed with practical ease of use in mind. Of course it works on the basis of a count of location records, but you can search the stock system by product code too. Most people select a range of location codes, then do their count in manageable chunks. This makes it very easy to do regular rolling stock counts. Much easier than a count of a whole warehouse.

Once the range of locations is chosen, the system moves from ‘selection mode’ to ‘count mode’. Counts sheets are printed, with or without existing quantities, and your staff can begin the count.

After the new quantities have been entered into the counts screen, the system will produce a ‘Stock Take Report’. This shows you all the quantity differences in the count, along with their cost. Of course this data is then saved back into the stock system and the stock take movements can all be reported on later if required.

Every stock take you do is saved in the system with its own reference number. It can be looked at again, and the Stock Take Report reprinted at any time.  Stock Management On Handheld DevicesThe ‘Stock Handhelds’ module allows your warehouse staff to manage the stock right in the warehouse, without the need to come back to the office to enter their data. Barcodes against stock locations mean that anything from Picking, to Stock Relocation, to Stock Takes can be done without the need for them to return to the office. In a large warehouse environment, especially if pipe is being sold, the rotation of stock is very important. The handhelds system is hugely valuable to getting the best efficiency out of your warehouse staff.

Stock Management On Handheld DevicesThe ‘Stock Handhelds’ module allows your warehouse staff to manage the stock right in the warehouse, without the need to come back to the office to enter their data. Barcodes against stock locations mean that anything from Picking, to Stock Relocation, to Stock Takes can be done without the need for them to return to the office. In a large warehouse environment, especially if pipe is being sold, the rotation of stock is very important. The handhelds system is hugely valuable to getting the best efficiency out of your warehouse staff.  Heat Numbers, Test Certificates And TraceabilityEvery item in the warehouse is assigned heat / cast and certificate numbers when it comes into stock. If you upload PDF files of the certificates into Softrader, you can produce them (or any other related documentation) at the click of a button. You can even email these documents to your client as soon as the delivery note is produced.

Heat Numbers, Test Certificates And TraceabilityEvery item in the warehouse is assigned heat / cast and certificate numbers when it comes into stock. If you upload PDF files of the certificates into Softrader, you can produce them (or any other related documentation) at the click of a button. You can even email these documents to your client as soon as the delivery note is produced.

Client logins can also be provided. These allow your customers to log in to Softrader and download their certs for themselves.

Stock System StructureThe structure of the stock system in Softrader Cloud is both practical and elegant. It works on 3 levels:

Stock System StructureThe structure of the stock system in Softrader Cloud is both practical and elegant. It works on 3 levels:

Stock Coding SystemSoftrader Cloud’s unique coding system is fully customisable and allows you to build up comprehensive specifications from which all your stock is coded.

Stock Coding SystemSoftrader Cloud’s unique coding system is fully customisable and allows you to build up comprehensive specifications from which all your stock is coded. Warehouse And Location ManagementIn Softrader Cloud, every stock item has a location in the warehouse or warehouses. Each unique combination of shipment, location, heat number and certificate number is identifiable to an exact point in the warehouse. Of course from this information it’s corresponding certificates can be found, and even any documentation relating to the original incoming shipment job.

Warehouse And Location ManagementIn Softrader Cloud, every stock item has a location in the warehouse or warehouses. Each unique combination of shipment, location, heat number and certificate number is identifiable to an exact point in the warehouse. Of course from this information it’s corresponding certificates can be found, and even any documentation relating to the original incoming shipment job. Consigned StockOne of the features of the warehouse system in Softrader Cloud is that consigned warehouses can be created. If you are storing your stock at your customers’ premises, this allows you to limit the sale of that stock to a particular customer or customers. It also allows you to report on stock movements and stock quantities and values in that warehouse.

Consigned StockOne of the features of the warehouse system in Softrader Cloud is that consigned warehouses can be created. If you are storing your stock at your customers’ premises, this allows you to limit the sale of that stock to a particular customer or customers. It also allows you to report on stock movements and stock quantities and values in that warehouse. Stock ReportingWhether it be a detailed Movement Report, or a report of all the stock in the warehouse, Softrader's detailed stock reporting capabilities will mean you are always on top of your stock's value, it's age, and what needs reordering in time for you never to run low.

Stock ReportingWhether it be a detailed Movement Report, or a report of all the stock in the warehouse, Softrader's detailed stock reporting capabilities will mean you are always on top of your stock's value, it's age, and what needs reordering in time for you never to run low. Stock TakesThe Stock Take system in Softrader Cloud is designed with practical ease of use in mind. Of course it works on the basis of a count of location records, but you can search the stock system by product code too. Most people select a range of location codes, then do their count in manageable chunks. This makes it very easy to do regular rolling stock counts. Much easier than a count of a whole warehouse.

Stock TakesThe Stock Take system in Softrader Cloud is designed with practical ease of use in mind. Of course it works on the basis of a count of location records, but you can search the stock system by product code too. Most people select a range of location codes, then do their count in manageable chunks. This makes it very easy to do regular rolling stock counts. Much easier than a count of a whole warehouse. Stock Management On Handheld DevicesThe ‘Stock Handhelds’ module allows your warehouse staff to manage the stock right in the warehouse, without the need to come back to the office to enter their data. Barcodes against stock locations mean that anything from Picking, to Stock Relocation, to Stock Takes can be done without the need for them to return to the office. In a large warehouse environment, especially if pipe is being sold, the rotation of stock is very important. The handhelds system is hugely valuable to getting the best efficiency out of your warehouse staff.

Stock Management On Handheld DevicesThe ‘Stock Handhelds’ module allows your warehouse staff to manage the stock right in the warehouse, without the need to come back to the office to enter their data. Barcodes against stock locations mean that anything from Picking, to Stock Relocation, to Stock Takes can be done without the need for them to return to the office. In a large warehouse environment, especially if pipe is being sold, the rotation of stock is very important. The handhelds system is hugely valuable to getting the best efficiency out of your warehouse staff.  Heat Numbers, Test Certificates And TraceabilityEvery item in the warehouse is assigned heat / cast and certificate numbers when it comes into stock. If you upload PDF files of the certificates into Softrader, you can produce them (or any other related documentation) at the click of a button. You can even email these documents to your client as soon as the delivery note is produced.

Heat Numbers, Test Certificates And TraceabilityEvery item in the warehouse is assigned heat / cast and certificate numbers when it comes into stock. If you upload PDF files of the certificates into Softrader, you can produce them (or any other related documentation) at the click of a button. You can even email these documents to your client as soon as the delivery note is produced.